Selecting the correct spoke type load cells for your tank or silo weighing application is critical for achieving accurate, reliable, and long-lasting performance. An improper choice can lead to measurement errors, frequent recalibration, or even premature sensor failure. This comprehensive guide walks you through the key factors and calculations needed to make the optimal selection for your specific tank setup.

Step 1: Determine the Total Weight Capacity Needed

This is the foundational calculation. You must account for the maximum possible weight the system will ever need to measure.

- Tare Weight (Empty Tank Weight): The weight of the empty tank, its structure, and any permanently attached piping, insulation, or platforms.

- Net Weight (Product Capacity): The maximum weight of the material the tank is designed to hold. Use the material's highest possible bulk density for conservative sizing.

- Dynamic Factors: Consider potential weight from snow, wind loading, internal pressure (for pressurized tanks), and process forces (like agitation).

Formula: Total Max Weight = Tare Weight + Net Weight (Max Product) + Safety Factor for Dynamic Loads

Step 2: Calculate the Load per Cell & Select Cell Capacity

Tanks are typically supported by 3 or 4 load cells. The load must be distributed evenly for accurate measurement.

- Decide Number of Supports (N): 3-point support offers inherent stability; 4-point is more common but requires a summing junction box with balancing resistors to handle minor tank floor deflection and uneven loading.

- Calculate Load per Cell: Max Load per Cell = Total Max Weight / N

-

Apply Safety Factor (SF): To ensure longevity and protect against overloads, never select a load cell with a rated capacity equal to the calculated max load. Industry standard is to apply a safety factor of 1.25 to 1.5.

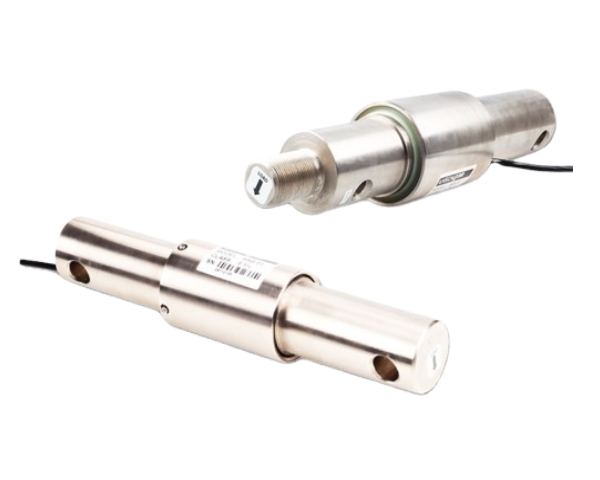

Selected Cell Capacity ≥ Max Load per Cell × Safety Factor (1.25-1.5) - Standard Capacity Selection: Choose the nearest standard rated capacity above your calculated value (e.g., 5t, 10t, 20t, 30t). Spoke type load cells excel in the 1-50 tonne range.

Step 3: Assess the Installation Environment

The environment dictates the required build material and protection rating.

-

Material:

- Alloy Steel: Standard choice for indoor, dry, non-corrosive environments. Most cost-effective.

- Stainless Steel (e.g., 304 or 316L): Essential for outdoor installations, food/chemical/pharmaceutical applications, washdown areas, or any environment with moisture, vapor, or corrosive agents.

-

Ingress Protection (IP) Rating:

- IP65/IP66: Dust-tight and protected against strong water jets. Suitable for most industrial settings.

- IP67/IP68: Submersible for limited periods/permanent immersion. Critical for tanks in flood-prone areas or with aggressive washdown procedures (e.g., food & beverage).

- Temperature Range: Ensure the load cell's compensated range covers your site's ambient and process temperature variations.

Step 4: Choose the Correct Mounting Configuration

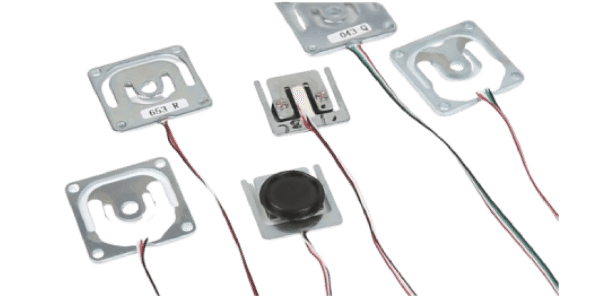

Spoke type load cells are versatile but require proper mounting hardware.

-

Compression Mounting (Most Common for Tanks): The tank sits on top of the load cell.

- Requires a load button on top of the cell and a base plate underneath.

- Ensure the tank support structure (legs, stools) is stiff and provides a flat, level mounting surface.

-

Tension Mounting: For suspended or hanging tanks.

- Requires clevis pins or threaded rods.

- Check Alignment: The load must be applied vertically and centrally to the cell. Use self-aligning load buttons or spherical bearings to compensate for minor structural shifts or thermal expansion.

Step 5: Consider System Accuracy & Signal Requirements

Define your precision needs to select the right performance class.

-

Accuracy Class: Spoke type load cells typically conform to OIML R60 or NTEP standards.

- C3 Class: Standard industrial accuracy (0.02% FS). Suitable for most inventory and batching control.

- C4/C5 Class: High precision for critical batching, custody transfer, or pharmaceutical applications.

-

Output Signal:

- mV/V Analog Output: Standard output; requires a nearby weight indicator or transmitter.

- Digital Output (RS485, CANbus, IO-Link): Offers superior noise immunity, longer transmission distances, and easier integration with PLCs and SCADA systems. Ideal for new installations.

- Cable Length & Entry: Specify sufficient cable length to reach the junction box. Choose top or side cable entry based on conduit routing and splash risk.

Step 6: Select Accessories for a Complete System

Load cells are only one part of a reliable weighing system.

- Junction/Summing Box: Mandatory for 4-cell systems. Balances signals from each cell and sums them into one output. Choose a sealed, high-quality model.

- Weight Indicator or Transmitter: Converts the summed mV/V signal into a readable weight value and provides outputs (4-20mA, Ethernet) for your control system.

- Overload Stops/Check Rods: Safety devices that prevent catastrophic damage to the load cells if the tank is overloaded or experiences extreme lateral forces (e.g., from earthquakes).

- Cable Protection: Use flexible conduits and proper strain relief to protect cables from damage, pests, and weather.

Common Mistakes to Avoid

- Undersizing: Selecting a cell capacity too close to the actual operating load, leading to early fatigue failure.

- Ignoring Side Forces: Not accounting for forces from connected pipes, thermal expansion, or agitators, which can cause binding and inaccuracies. Use flexible couplings on all piping connections.

- Poor Foundation: Installing on a flexible or uneven foundation that shifts, causing load redistribution and measurement errors.

- Mixing Old & New Cells: Never replace just one failed cell in an existing system. Always replace the complete set and recalibrate.

- Skipping Professional Calibration: On-site calibration by a certified technician is essential after installation and during periodic maintenance.

Conclusion & Professional Recommendations

Choosing the right spoke type load cell for your tank weighing system is a systematic process that balances engineering calculations with practical environmental and installation considerations. By carefully determining the total load, applying appropriate safety factors, selecting corrosion-resistant materials for your environment, and integrating proper mounting accessories, you can ensure a system that delivers years of accurate and trouble-free service.

For complex applications or if you are unsure about any selection parameter, consult with a weighing specialist. At Galoce, our application engineers can help you specify the perfect load cell system for your tank, from the sensors and mounting hardware to the junction box and calibration services. Get in touch for a free technical consultation to optimize your tank weighing investment.